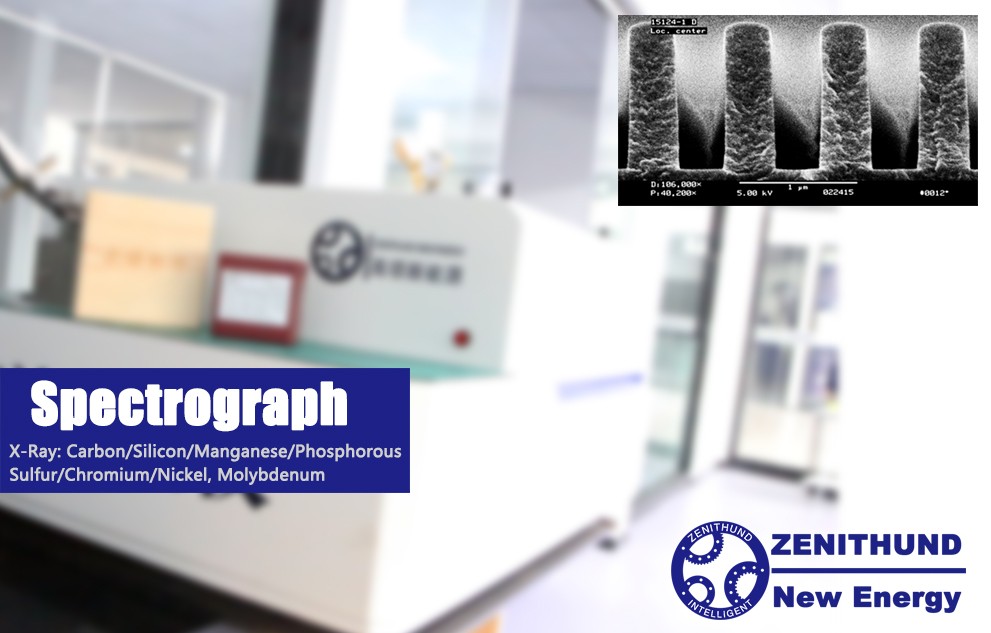

Direct reading spectrometer can quickly and accurately analyze the content of various elements in slewing bearing materials, including carbon, silicon, manganese, phosphorus, sulfur, chromium, nickel, molybdenum and other elements. By analyzing the content of these elements, it can be determined whether the chemical composition of the raw material meets the standard requirements, and whether it needs to be adjusted and optimized.

In addition, the direct reading spectrometer can also analyze the alloy elements and impurity elements in the slewing bearing material to evaluate the purity and quality of the material. Through the analysis of these elements, the quality of raw materials can be effectively controlled to ensure that the manufactured slewing bearing products meet the requirements and have a long service life.

In short, the direct reading spectrometer is one of the indispensable analytical instruments in the manufacturing process of slewing bearings, which can help manufacturing enterprises to achieve comprehensive detection and control of raw materials and improve product quality and reliability.

Direct reading spectrometer is an analytical instrument based on the principle of spectroscopy. It has the characteristics of high precision, fast and convenient, and is widely used in various fields. This article will introduce the basic principles, characteristics and application scenarios of the direct reading spectrometer.

1. Basic principles

The direct reading spectrometer mainly uses the principle of spectroscopy to excite the substance through electric spark, electric arc or laser to generate emission spectrum, and measure and analyze the spectrum. The basic principle is: when a substance is excited, an emission spectrum will be generated, and these spectra contain various chemical composition information of the substance. By analyzing these spectra, the type and content of elements in the substance can be obtained.

2. Features

High precision: The direct reading spectrometer has very high measurement precision, which can realize the precise measurement of element content, and the measurement error is usually within 1%.

Fast: The direct reading spectrometer can measure the content of multiple elements at the same time, and the measurement speed is very fast, which is suitable for the rapid analysis of large batches of samples.

Convenience: The direct-reading spectrometer is easy to operate, sample preparation is simple, and does not require complicated chemical treatment processes, and can directly analyze solid samples.

Multi-element analysis: The direct-reading spectrometer can analyze multiple elements at the same time, including carbon, hydrogen, nitrogen, oxygen, sulfur and other elements, and is suitable for the analysis needs of multiple elements.

3. Application scenarios

The direct-reading spectrometer can be used for elemental analysis in slewing bearings and slewing drive turntables.

4. Conclusion

Direct reading spectrometer is an analytical instrument based on the principle of spectroscopy. It has the characteristics of high precision, fast and convenient, and is widely used in various fields. Its application scenarios include petroleum exploration, chemical industry, environmental protection, material science, etc. With the continuous development of science and technology, the direct reading spectrometer still has a lot of room for development in the future and will be applied in more fields.

Recent News

Top ranking