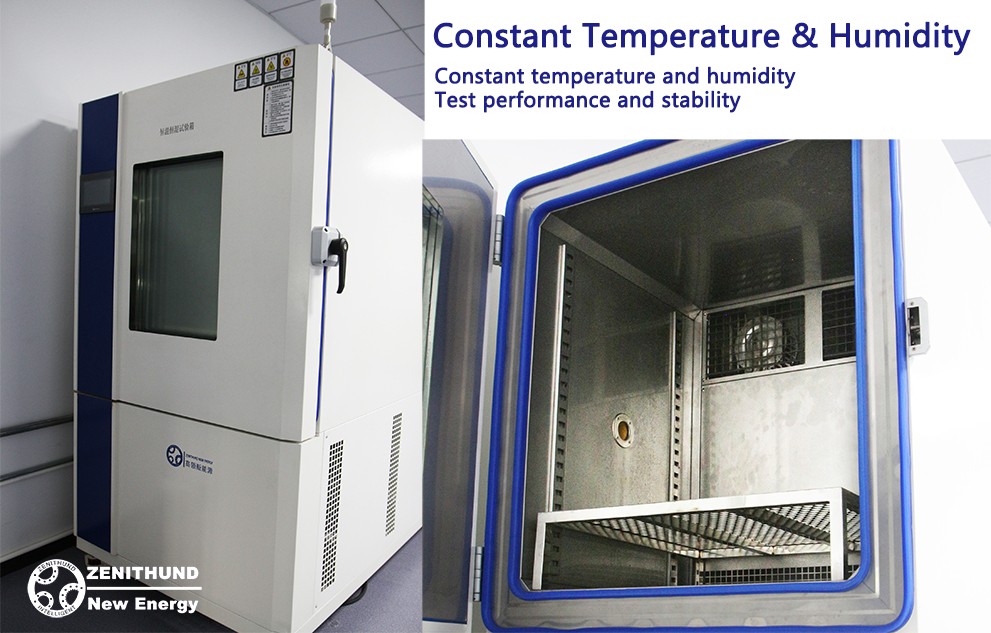

The purpose of running the slewing drive simulation test in a constant temperature and humidity environment is to test its performance and stability under different environmental conditions. By testing in a constant temperature and humidity environment, the operation under different climatic conditions can be simulated to evaluate the adaptability and reliability of the slewing drive simulation.

During the test, the slewing drive simulation equipment needs to be placed in a constant temperature and humidity environment, and it should be operated and monitored accordingly. Usually, various data need to be recorded during the test, such as equipment operating status, temperature, humidity, current, voltage, etc. These data can be used to analyze the performance and stability of the device under different environmental conditions, as well as to detect possible failures or abnormal conditions.

In addition to running tests, there are other ways to evaluate the performance of the slewing drive simulation, such as component-level testing, simulation analysis, etc. These test methods can further verify the performance and reliability of the device and help developers optimize and improve it.

Testing the slewing drive to run in a constant temperature and humidity environment is an important step to evaluate its performance and stability, which can ensure the normal operation of the device under different environmental conditions, and provide feedback and improvement suggestions for developers.

Recent News

Top ranking