Boggi Bearing

Bogie bearings play an important role in the boggi system. The bogie is an independent component of the vehicle, and there are as few connecting parts as possible between the bogie and the vehicle body. The boggi bearing can maintain the soft connection between the wheel and the bogie, and the rolling of the wheel along the rail is converted into the translational motion of the car body running along the line through the bearing device. At the same time, it also supports the car body, bears and transmits various loads and forces from the car body to the wheels or from the wheel rails to the car body, and evenly distributes the axle load. In addition, boggi bearings can also ensure the safe operation of the vehicle and the flexibility to run along straight lines and smoothly pass curves. In terms of structural design, the bogie bearing needs to facilitate the installation of the spring damping device so that it has good damping characteristics to ease the interaction between the vehicle and the line, reduce vibration and impact, reduce dynamic stress, and improve the vehicle Operational smoothness and safety.

The steps to replace bogie bearings are as follows:

Remove the failed bearing. The best option is to use a puller and a press. Using the puller to safely pull the bearing out of the outer ring can minimize damage to the shaft and housing and save time. If a puller is not available, a separator can also be used to remove the bearing. It is not recommended to use the removed bearing again, but it is necessary to carefully inspect the removed bearing to determine the cause of the bearing failure and summarize experience to protect the bearing when it is used in the future.

When installing new bearings, special care is required. The first is to ensure a clean, dry, vibration-free storage space. Do not open the bearing package before installing the bearing unless required by the instructions. Before starting installation, make sure the bearing housing and shaft are clean and free of burrs. When installing you need to make sure to measure the housing bore and shaft to make sure they are within the recommended tolerances for the bearing and machine.

Please note that the above steps are for reference only and may not apply to all situations. In actual operation, it is also necessary to consult professionals for advice and guidance.

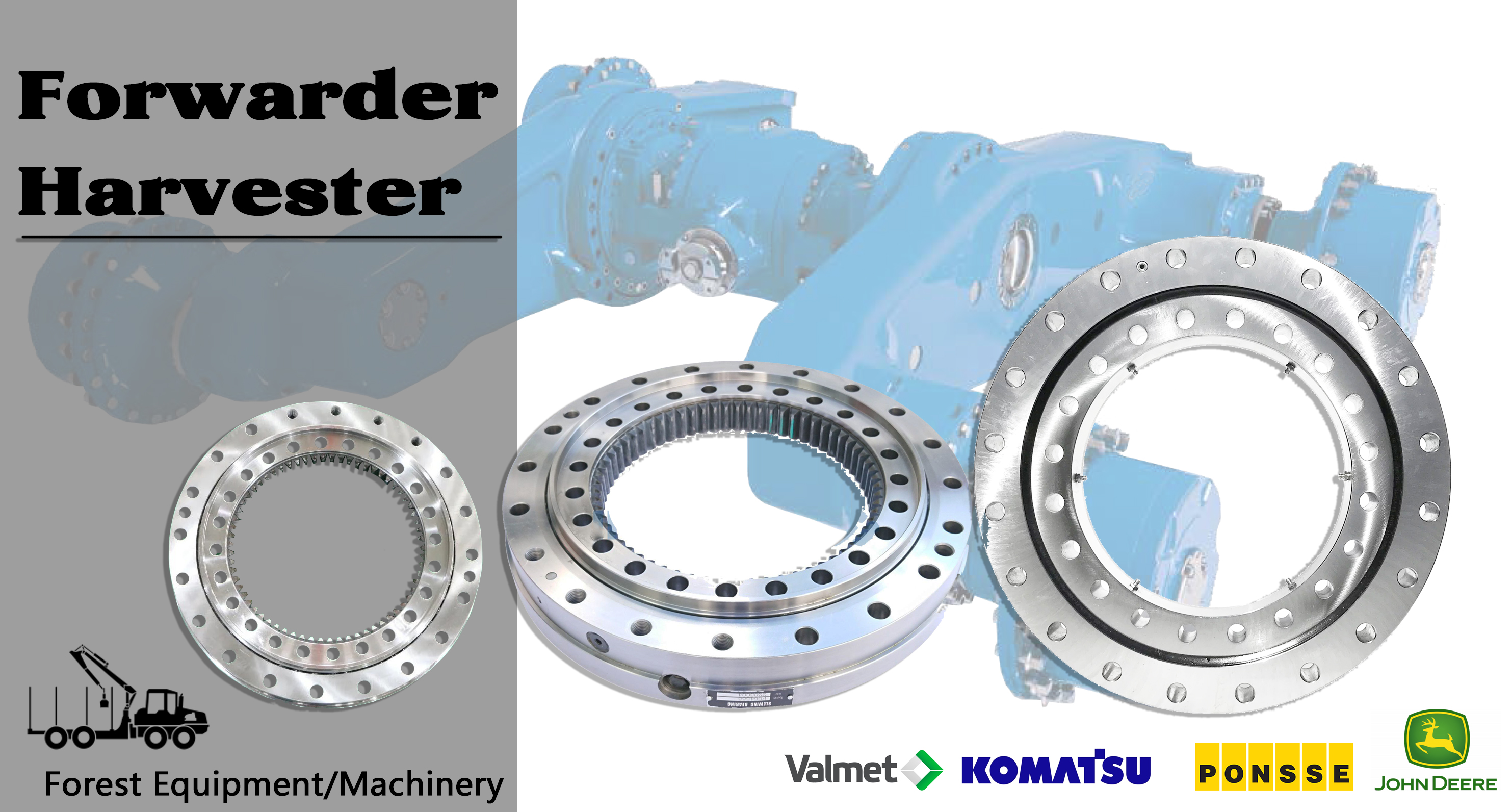

Our company can produce the following boggi bearing replacements:Swing bearing bogie

F064588/064588A/F054729/5035589/F064588/F034628/5058357/F064720/F033618/F075460/

5078484/5258171/0073266/P41730;PONSSE/NAF7305034;PONSSE/NAF7305047;PONSSE/0047880;PONSSE/NAF7305050 PONSSE/0068323;PONSSE/0068322;PONSSE/0058064;PONSSE/0073266;PONSSE/0074268;PONSSE/0074254 PONSSE/NAF7305046 PONSSE/0074385 PONSSE/0070651 PONSSE/0074387 PONSSE/

John Deere:F033618/F016322/F075460/F681170/F065391/F053037/F054729/F064588/F065070/F054938/F065418

Ponsse:58064/74268/65997/68322/68323/NAF7305034/NAF7305047/NAF7305050/74387/P24313/P27266/P41730/0064361/0074254/47880/67021/74385/74386/79094/

Valmet/Komatsu: 5236291/5035589/5058357/5044240/5082430/5078484/

- previous:German solar tracker(2023/11/10)

- next:Gansu Yumen Photovoltaic\Wind Power(2023/11/23)

Recent News

- 1Persistence & Struggle The Spring Festival

- 2Detection of failed slew drives

- 3European companies visit our solar reducer production line

- 4PV tracking system

- 5Gansu Yumen Photovoltaic\Wind Power

- 6Boggi Bearing

- 7German solar tracker

- 8Brazil builds new solar tracker factory

- 9SKF Slewing Bearing

- 10CSP Dual-Axis Slew Drive

- 11SE WE WD Slewing Drive

- 12Concentrated Solar Power(CSP) Slewing Drive

- 13Solar Tracker Designe

- 14Solar Slew Drive Price

- 15Slewing Drive Price

Top ranking

- 1Solar Photovoltaic Exhibition in Munich, Germany in 2023

- 2Slewing drives in the High Girder Bridge Trailers

- 3CSP Dual-Axis Slew Drive

- 4SE WE WD Slewing Drive

- 5SKF Slewing Bearing

- 6Brazil builds new solar tracker factory

- 7German solar tracker

- 8Boggi Bearing

- 9Analysis, scale, share of slewing drive industry in 2023, and prediction of Market trend by 2030

- 10Gansu Yumen Photovoltaic\Wind Power

- 112032 Single-Axis Solar Tracker Market

- 12By 2029, the slewing bearing market will reach 8.64 billion US dollars

- 13Features of double-axis solar tracking reducer

- 14Rotary Drive Market

- 15Arctech releases a dual row single axis solar tracker